The limitation in this process is the width of the ink which can’t get any smaller than 0.007 inches.

ALLEGRO CHANGE LAYER ITEM IN XSECTION IMAGE MANUAL

Manual silkscreen printing: This is the standard method of printing markings on a PCB by using a stencil as a template and pushing a non-conductive ink through a polyester screen onto the board. Below you’ll find all the silkscreen processes available and why you may or may not want to use them: And while it is true that a manual silkscreen process is still used to create markings on a PCB, there are two other processes available as well. Printing the silkscreen onto the board is one of the last steps to be completed during printed circuit board fabrication.

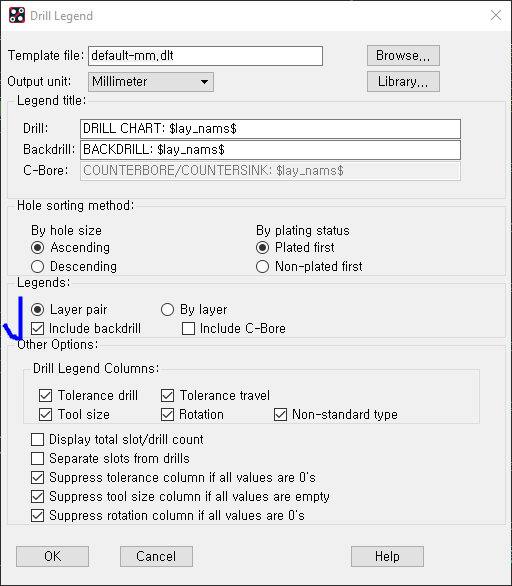

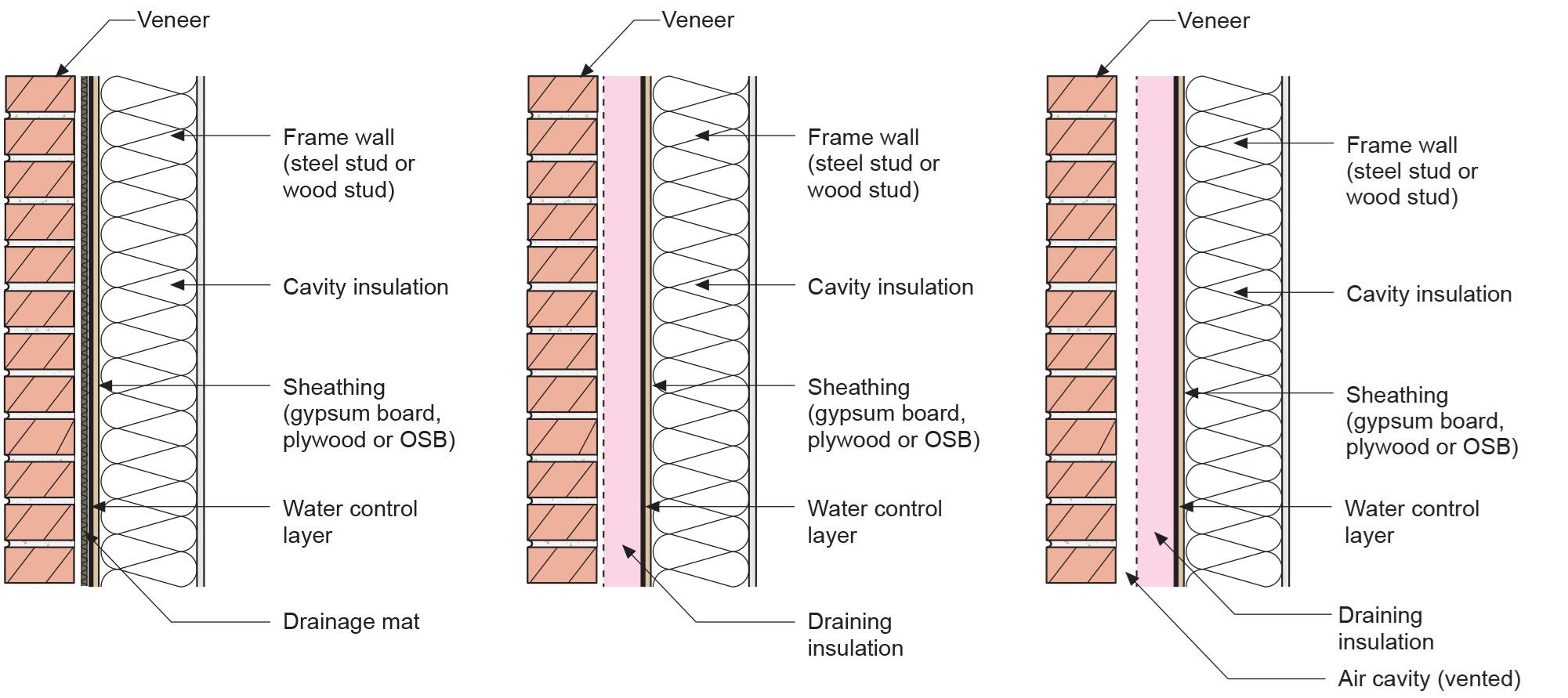

This is why the CAD tool layers devoted to these markings are referred to as the silkscreen layers. Silkscreen is not only a type of printing process used to apply identification markings on a printed circuit board, but it is also the generic term used to describe the ink markings themselves. PCB Silkscreen: What It Is and What It’s Used For Let’s take a closer look at the PCB silkscreen process and some recommendations for silkscreen design best practices. How the images are rendered on the circuit board depends on the method used by the PCB designer in managing silkscreen layers and PCB stackup information in their CAD system. What is less known is that a variation of this process has been used for years to create images and markings on printed circuit boards. Today, most people are familiar with silkscreen printing being used to create their favorite images and patterns on T-shirts. This resulted in it being given the name that it is known by today. Around the 15th century, silkscreen printing found its way to the West, where the original material used for the screen was silk. Stencils have been used throughout history to decorate the tombs of pharaohs and produce various religious images. Silkscreen printing with stencils is an art form that has been around for a long time. How constraint management can help with the design of your PCB silkscreenĪdjusting silkscreen on your PCB - moving text to open space and changing the orientation for better readability. Managing the silkscreen and other informational layers within the CAD database I tried setting it to 1, which the foreground layer is for the map, but it still won't draw it when I run the program.The origins of the PCB silkscreen and what it is used for I see that for the MapDrawFG() on line 178, the only difference from MapDrawBF() on line 175 (which seems to be working) is that the last element passed is an int which specifies which layer to draw. They define a lot of things to get the mappy files to work with Allegro.but, being the newb that I am, I'm having trouble figuring out what I need to do.but I'm sure the answer is lying somewhere in those files.Įdit - in the REDMEAL.TXT file, it goes over some things. I attached a couple files that are associated with this example program. When I try loading map1, it will show layer 0, the sky and clouds, but the foreground isn't showing. The foreground (layer 1) is everything else so far.the ground, obstacles, etc. The background (layer 0) is the sky, clouds, etc. The first map (map1.fmp) has 2 layers so far:

They are both older programs, but I know that they can work accomplish what I need to accomplish. I am using Mappy to create the maps and Tile Studio to create the tiles for the maps. 1 #include 2 #include 3 #include "mappyal.h" 4 5 #define MODE GFX_AUTODETECT_WINDOWED 6 #define WIDTH 640 7 #define HEIGHT 480 8 #define JUMPIT 1600 9 10 //define the sprite structure 11 typedef struct SPRITEġ2 204 END_OF_MAIN ( )

0 kommentar(er)

0 kommentar(er)